2.7 Volt lightmeter power board for Nizo super8 camera

Presenting the latest solution for a 2.7Volts regulator circuit, to create a permanent solution for powering the lightmeter of the Nizo 8xx/5xx/4xx family of super8 cameras. These cameras normally require 2 buttoncell batteries of 1.35V each, which are hard or nearly impossible to come by nowadays.

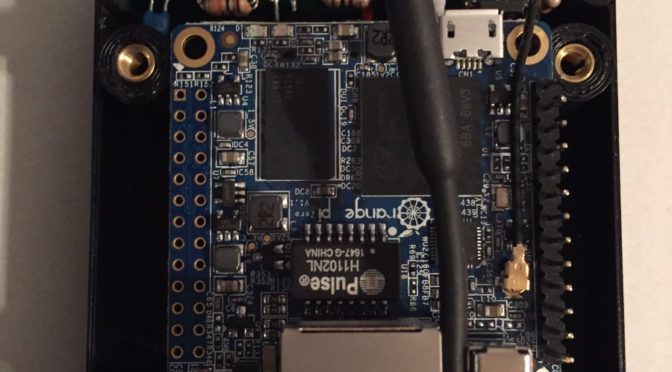

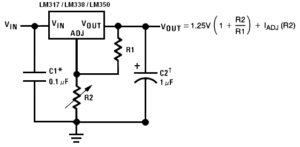

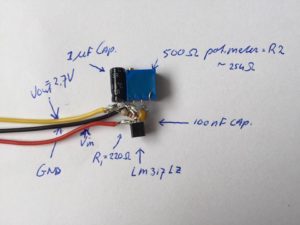

We developed a new solution, on a dedicated tiny printed circuit board (10mm x 10mm), with only 3 components. It can be connected to the main battery supply of the super8 camera, and it supplies a rock-solid, constant 2.7 Volt output voltage that can be connected to the light meter circuit.

The circuit is designed around a dedicated voltage regulator IC. Packaged in a small SMD design this IC allows for a very small board design. Complemented with 2 capacitors the circuit board is a mere 10mm x 10mm in size. As a result it allows easy placement into the button-cell light meter battery container.

See this video for explanation and example installation of the regulator board into a Nizo 801 Macro super8 camera:

The board has GND (black wire soldered to pad) and Vin (red wire soldered to pad) inputs and one Vout 2.7Volt output (the camera 2.7V lightmeter wire (usually yellow in Nizo’s) can be soldered to it). The EN pad can be left unconnected.

It is strongly advised to ensure that precautions are taken to isolate the board electronically to prevent short-cuts to ground. This is because the metal parts of the camera and the button-cell battery container cover are connected to ground. Using the provided shrink tube is advised.